Workplace Electrical Safety Guide

Understanding and implementing workplace electrical safety practices is critical for all businesses to keep their employees physically safe. Over 1500 workers each year get injured by electricity while on the job, and approximately 160 individuals end up losing their lives. The likelihood of electrical injuries or fatalities occurring in the workplace can be dramatically reduced if employees are made aware of the possible risks associated with electricity, as well as how they can stay safe while completing their responsibilities.

Workplace Electrical Safety: What Are the Possible Dangers of Working Near Electricity?

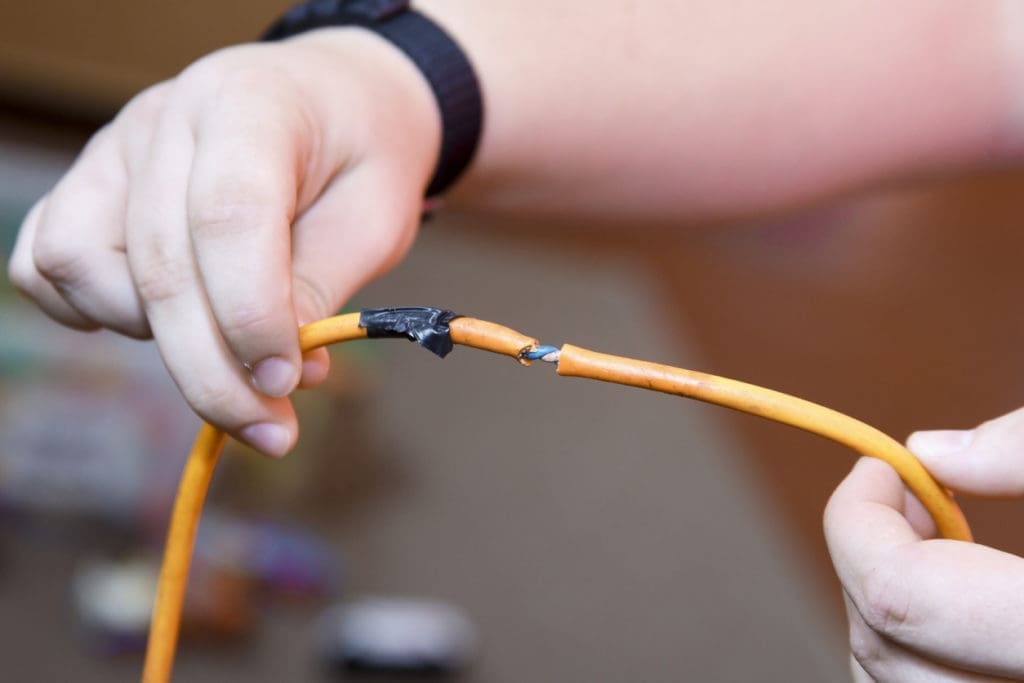

Although electricity provides us with many modern benefits, it can also cause us great harm if we are not careful. Faulty wiring, overloaded outlets, poor insulation, and many other electrical situations can become dangerous or fatal within a matter of seconds.

When electricity is dynamic, that means that the electricity is moving through a conductor. You probably know already that metal is a conductor. That’s why it’s best to cook on a stove with silicon or wooden utensils, and to never put metal in an outlet socket. But humans can be conductors for electricity too, which is why you and your employees need to practice great caution around electrical devices.

The most common type of electrical injury is caused by an electrical shock, which can cause muscle spasms, difficulty breathing, or irregular heartbeats. Electrical dangers can also lead to fires and explosions that could cause your employees to experience severe falls, burns, or lung collapses.

How Can You Implement Effective Workplace Electrical Safety Policies For Your Employees?

Improper or negligent behavior around electricity can lead to disastrous consequences in the blink of an eye. However, with proper training in workplace electrical safety precautions, you and your employees can effectively accomplish your duties with much less risk of injury.

General Guidelines

- Avoid using electrical equipment near water or with damp hands. If you have to work near water, be sure that you are only using ground fault circuit interrupters (GFCIs), which are a type of outlet designed to reduce your chances of electric shock. If you aren’t certain about the kind of outlet available to you, invest in a portable in-line GFCI.

- Turn off electrical appliances when not in use. Make sure that electrical devices are either switched off or unplugged if you are cleaning or repairing that device. Even if you are just in the vicinity of that electrical appliance, it’s best to turn it off before proceeding with your work.

- Be on the lookout for warning signs. Dangerous electrical equipment might emit strange smells or noises. It could also feel unusually hot to the touch, give off sparks, or start smoking. Immediately disable any electrical cord or device that may not be fully operational.

- Only use equipment that is laboratory-approved. All of the electrical equipment that your business uses should be approved by a testing laboratory with national accreditation.

- If an electrical injury occurs, do not touch the person or appliance. While of course our first instinct is to help a wounded coworker or employee, doing so could cause electrical harm to you, too. Your first step should be to safely disconnect the power source before tending to any injuries.

Power Cord Guidelines

- Don’t clutter doorways or walking paths with cords. If a cord must cross a frequently traveled path, then the cord should be hung from the walls or bound to the floor.

- Never use staples, nails, or wires to hold power cords in place. Only tape should be used to avoid starting a fire or explosion.

- Avoid plugging in one extension cord to another. Plugging two extension cords together reduces their capacity to conduct electricity. This often causes the cords to overheat and puts your business at great risk for starting a fire.

Power Tool Guidelines

- Switch off tools before plugging them in. Tools shouldn’t be turned off and on by the electrical plug.

- Be mindful of how a plug fits into a socket. Plugs should always be secure when plugged into an outlet, as loose plugs can lead to overheating. However, it is also crucial to never force a plug into an outlet that is too small, as this increases the risk of electrical shock.

- All tools should be either double-insulated or properly grounded. Double-insulated tools will either have this fact written on their casing or have the international symbol for double insulation (a square within a square). For grounded tools, make sure you have a 3-wire cord and a 3-prong plug.

Power Line Guidelines

Non-electrical workers are not allowed to work close to power lines. The exact distance that you need to keep from power lines varies by location and power company, so make sure you read up on the local laws for where your business operates. Generally, non-electrical workers need to keep their vehicles, equipment, and themselves about 49 feet away from power lines.

If you do need to work near power lines, adhere to the following guidelines:

- Only use ladders that will not act as conductors. Ladders used near power lines must be undamaged and dry. They should also be made from non-conductive materials, such as fiberglass, as opposed to metal.

- Do not work in bad weather conditions. If you work on a windy day, the risk of power cords swaying, or your ladder shifting position, increases dramatically. Additionally, working in the rain heightens the chances of electrical shock, as water is a very good conductor.

- Contact the local utility company. This is required by law when working near power lines. The power company local to the area can assist you in keeping your employees safe.

Canal HR Can Help Your Business Promote Workplace Electrical Safety

At Canal HR, we have plenty of experience helping businesses optimize their workplace electrical safety procedures. Our Risk Manager will examine your worksite for potential dangers and suggest ways for you to dramatically reduce the risks for your employees. In case your employees do get injured while on the job, we also offer a human resources outsourcing program that provides cost-effective worker’s compensation. Contact us today to learn more about how our safety and risk management team can help your business devise and implement stronger workplace electrical safety guidelines.